The Plant has all the facilities for normalizing, annealing and heat treatment and also is fully equipped with all testing facilities for physical, chemical and ultrasonic testing. Each of the Product undergoes rigid testing and inspection at various stages from raw material to finished products. Forging is done in controlled temperature conditions.These quality objectives are measurable i.e. we can measure the reduction in rejections, rework, wastage, breakdown time, un-planned down time, optimum utilization of the available resources and timely delivery to the customers.

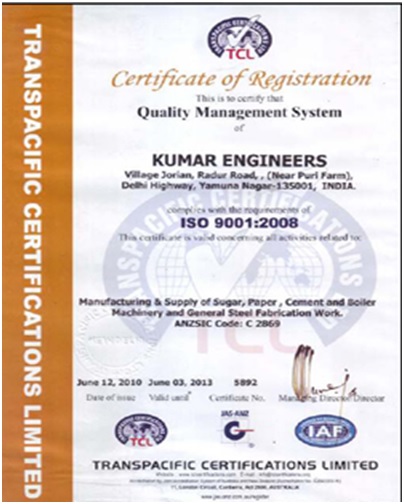

Quality Policy :

Kumar Engineers shall achieve Total customer satisfaction by providing quality forgings on continuous improvement basis, under reasonable cost & within agreed time frame.